Brain-computer interface is expected to enter the "5G" era

When it comes to brain-computer interfaces, the first thing that comes to your mind is Neuralink, a company founded by Elon Musk. They just implanted the first chip into the human brain in January this year .

But Neuralink is by no means the only company working on brain-computer interfaces.

On May 28, Precision Neuroscience announced that they had successfully placed 4,096 neuron-stimulating electrodes on the human brain, setting a new world record.

The number of electrodes is a key metric in the field of brain-computer interfaces because it determines the "bandwidth" of the brain's data transmission, thus affecting the functionality of the interface system.

In other words, increasing the number of electrodes can improve the efficiency of transmitting data from the brain to the outside world.

The previous world record was a paper published in the Journal of Neurosurgery last September, in which they placed 2,048 electrodes on the human brain.

Unexpectedly, this number doubled in just 8 months. It can be said to be a replica of Moore's Law in the field of BCI.

Layer 7 ultra-thin electrodes, micro-slit insertion

If you want to understand the activities of the human brain, it is far from enough to perform electroencephalogram (EEG) or magnetic resonance imaging (MRI) from the outside. Therefore, there is a technology to implant electrodes into the brain. The array they form can collect information from multiple points in the cerebral cortex at the same time.

And the number of electrodes is important. If you want patients to be able to control a prosthetic limb or move a cursor on a screen with their thoughts, a few dozen electrodes are not enough. Even basic functions require a high density of electrodes.

Can the problem be solved by increasing the number of electrodes?

No, because each electrode will pierce the brain tissue and cause damage. Expanding from 100 electrodes to 1,000 electrodes means 10 times the damage.

To achieve high-density electrode implantation, it needs to be deployed in a minimally invasive manner and have good scalability.

Therefore, Precision used an innovative technology to solve this problem.

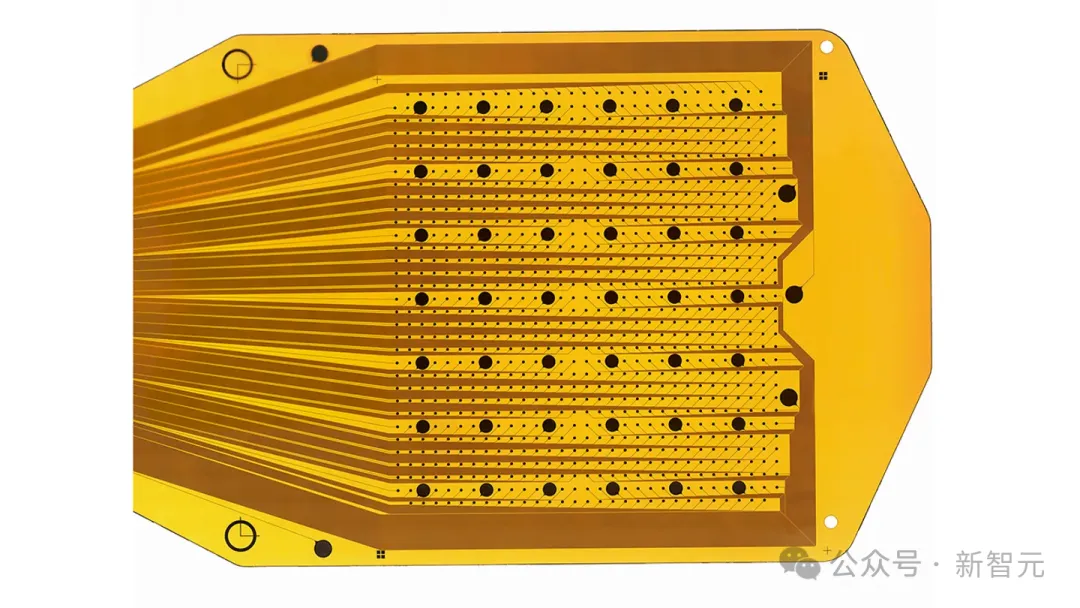

They developed an ultra-thin electrode array called Layer 7 that can be implanted without puncturing the brain but can collect hundreds of times more data than traditional arrays.

It is named Layer 7 because the cerebral cortex itself has 6 layers, and this thin film composed of electrodes is located at the top of the cortex, which is the 7th layer.

A single Layer 7 is slightly larger than a thumb nail but only one-fifth the thickness of a human hair. It can densely arrange 1,024 tiny electrodes, each of which is comparable in size to a neuron.

Precision's record-breaking implantation of 4,096 electrodes was achieved by placing four Layer 7 films on the surface of the brain at the same time.

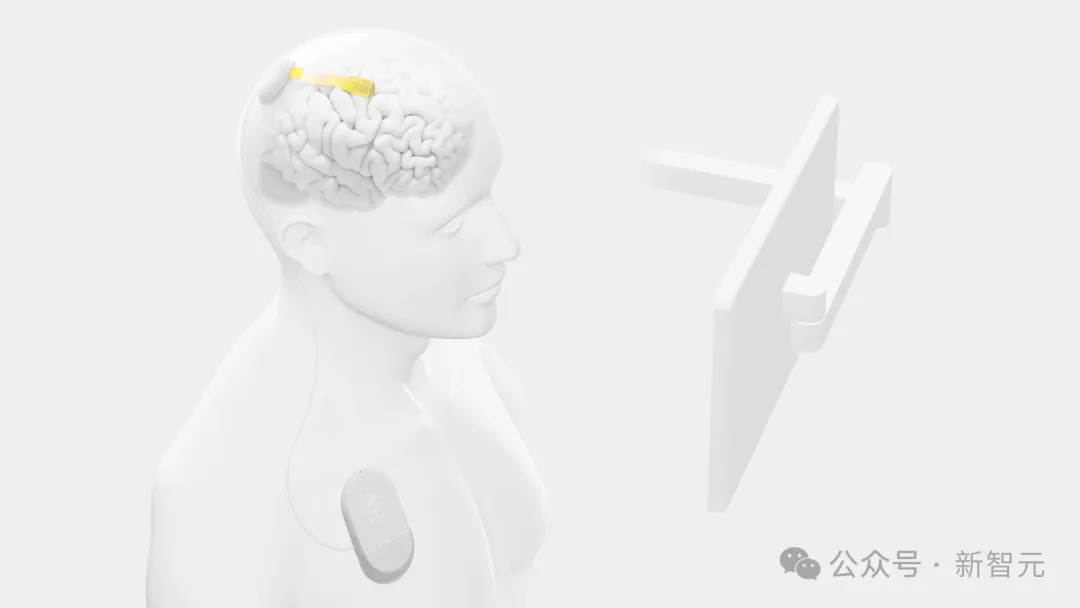

These electrodes can receive brain signals and transmit them to a processing unit located between the skull and scalp, and then pass them to a processing unit in the chest through wires placed under the skin and forwarded to the outside world.

Why are these electrodes able to transmit brain signals?

Each electrode is connected to the electronics via an extremely thin platinum wire and is arranged in a modular lattice structure, so that it covers the surface of the brain in a very regular geometric pattern.

Moreover, the electrode arrangement density is high enough, and after receiving a large number of electrical signals from the brain, it can draw a map of brain electrical activity in a certain area with very high resolution.

The continuously output EEG signals will constitute massive amounts of data and contain a lot of noise, so the connected electronic devices will also need to perform compression and denoising work.

Array simulation of the Layer 7 cortical interface.

To understand these EEG signals, machine learning is also needed.

Expressing EEG signals in an understandable form is a task similar to machine translation.

Neuroscience research can tell us the general function of each brain region, such as which area is responsible for language and which is responsible for controlling hand movements.

However, this domain knowledge alone is far from enough, because everyone's brain is structured differently. Even if the same function is performed, the location of the corresponding specific electrical signals will be different.

Software based on machine learning can "learn" each person's brain structure, calibrate the location of brain areas, and translate and interpret EEG signals.

Michael Mager, CEO of Precision, said that BCI is more than just an electrode array. “The complexity of machine learning is a must to drive a truly powerful BCI. This is a full-stack product that requires an interdisciplinary team to develop.”

Implantation of Layer 7 film does not require craniotomy. It can be inserted through an incision less than 1 mm thick on the skull and "slide" to the surface of the brain, which is much less invasive and harmful.

The process is called "micro-slit insertion," and patients who undergo the implants don't even need to shave their hair, making it look like they haven't had major surgery.

Another thing to consider is that all equipment has a lifespan and requires repairs and replacements.

According to Precision, the interface created by Layer 7 is reversible and the brain remains intact after implantation, which can reduce this risk.

Layer 7's cortical surface array and non-invasive procedure are patented and unique to Precision.

In the view of the company's founder Benjamin Rapoport, the security and good scalability of this technology are very worth looking forward to.

The "communication bandwidth" of the brain-computer interface is proportional to the number of electrodes. Placing more Layer 7 on the surface of the brain will not cause any additional brain damage or increase any risks.

Therefore, it is conceivable that the communication capabilities of brain-computer interfaces will gradually increase from 3G to 4G, and then to 5G and 6G, possibly transmitting entire ideas or intuitions instantly, which will completely change the nature of human-computer communication and even communication between humans.

The technology is still in the clinical testing phase, but they conducted their first human implant last year and expect the first commercial product to be on the market in 2025.

Leaving Neuralink and starting his own business

If you dig deeper into the company Precision, you will find that it has a close connection with Neuralink.

The company's founder Benjamin Rapoport and Musk once co-founded Neuralink, but he chose to leave in 2021 and raised $12 million to establish Precision.

Of the company’s founding team of four, three had previously worked at Neuralink.

Rapoport, who has a PhD in electrical engineering and computer science from MIT and a medical degree from Harvard Medical School, describes himself as having "dedicated almost his entire career to bringing neural interfaces from the scientific world to the medical world."

In the view of the company's CEO Michael Mager, Rapoport, as a neurosurgeon and electrical engineer, has always been a "pioneer" in the BCI industry. He defined the key features of Precision's key technology Layer 7.

In a podcast of the Wall Street Journal, Rapoport was asked why he left Neuralink. He did not answer directly, but described the differences between him and Neuralink in terms of technical concepts.

I feel like in order to get into medicine and technology, safety is of utmost importance. For medical devices, safety usually means the least invasive.

Early brain-computer interfaces had a concept: in order to extract information-rich data from the brain, it was necessary to penetrate the brain with tiny needle electrodes, but this would cause a certain degree of brain damage.

We founded Precision Neuroscience with the belief that we could extract information-rich data without damaging the brain. We believe that minimal invasiveness, scalability, and safety are important foundations for neural interfaces.

This conflict in concepts is also reflected in the actual technological paths of the two companies.

The system currently used by Neuralink is based on penetrating microelectrodes, which require craniotomy, opening most of the skull, and high-precision implantation by a robot, while Precision's Layer 7 is based on surface microelectrodes that cover the surface of the brain but do not penetrate.

After Neuralink implanted the device in its first patient, the penetrating microelectrode did experience mechanical failure.

Within weeks of surgery, the wires holding the electrodes embedded in patient Noland Arbaugh's brain tissue began to retract, rendering the device inoperable.

Industry insiders said complications may have occurred because the wires were connected to a device inside the skull rather than to the surface of brain tissue.

“Engineers and scientists didn’t realize how much the brain moves in the intracranial space,” says Eric Leuthardt, a neurosurgeon at Washington University School of Medicine in St. Louis. “Just nodding or moving your head suddenly can cause a perturbation of a device by a few millimeters.”

According to a recent report from the Wall Street Journal, 85% of the wires in the patient's brain have become loose and cannot function properly. One of the solutions proposed by Neuralink is to implant the device deeper into the cerebral cortex, moving it from 3-5 mm to 8 mm.

Despite such fundamental differences in the same field, in Precision's eyes, Neuralink is a colleague rather than a competitor.

The company's CEO Mager said, "We use different approaches, suitable for different situations," "This will not be a winner-takes-all market, there is room for more than one company to develop."

But one thing is the same for them - they all need to prove the safety of the system and pass the complex approval and regulatory process of the FDA. After entering the market, they also need to consider how to reduce the cost to a level acceptable to patients.

These are tasks as daunting as the technology itself.