How to choose optical module?

How to choose optical module?

As a bridge between data center servers and switches, optical modules are one of the essential products in data centers. At present, there are many types of optical modules on the market, and the quality is uneven. If you choose an inappropriate optical module, it will lead to problems such as slow network speed and instability.

Correct selection of optical module parameters is the first step in optical communication network transmission.

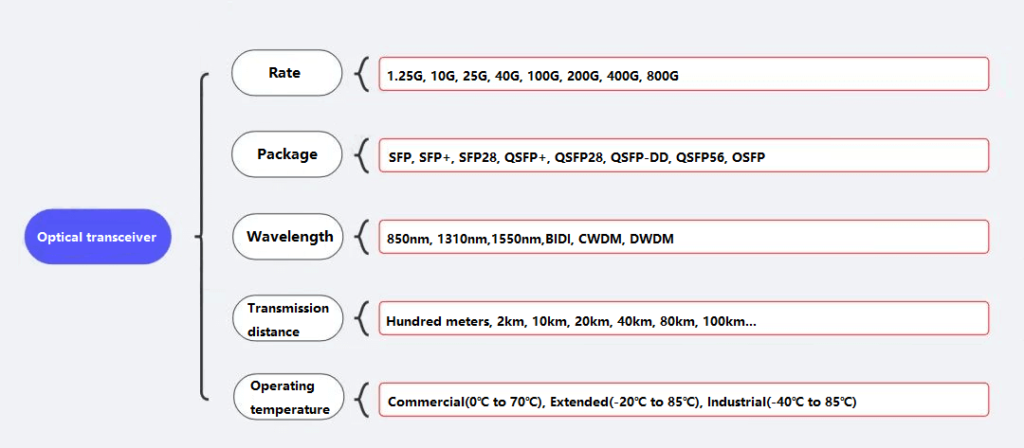

Before purchasing an optical module, you should first understand the network environment and usage requirements. For example, optical module parameters include transmission rate, packaging method, operating wavelength, transmission distance, operating temperature, etc. These are key references for optical module selection.

How to choose optical module?

How to choose optical module?

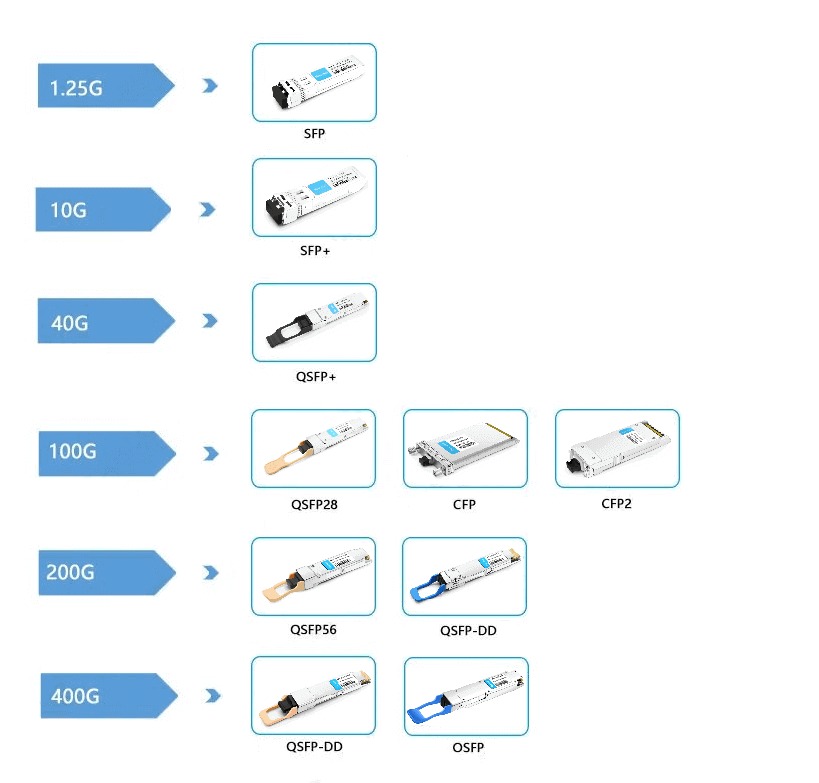

Transmission rate and encapsulation method

How to choose optical module?

How to choose optical module?

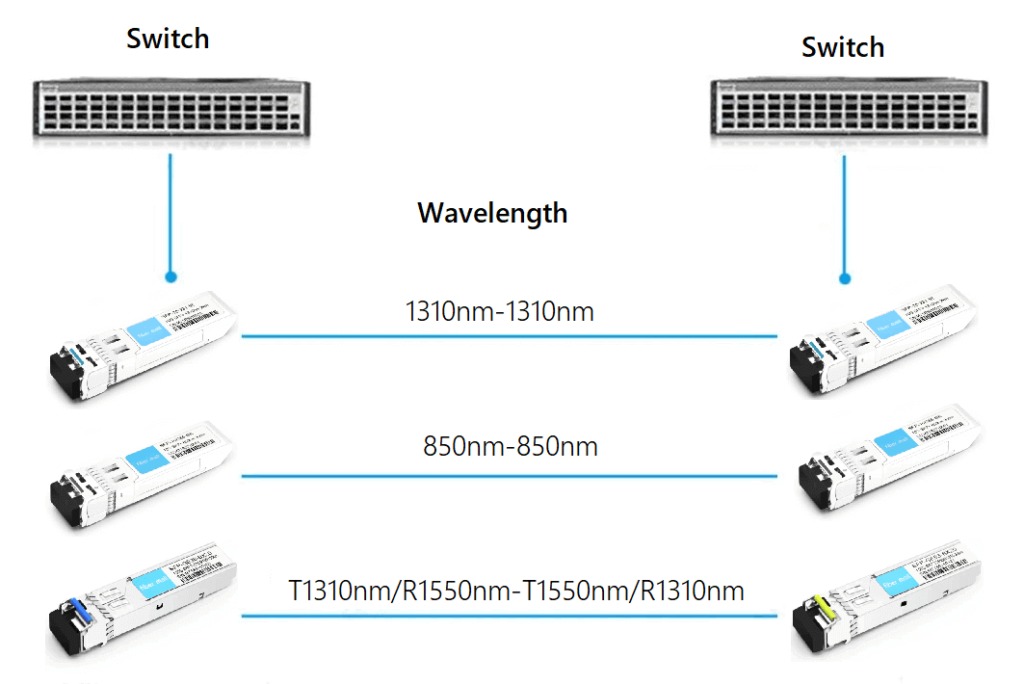

wavelength

How to choose optical module?

How to choose optical module?

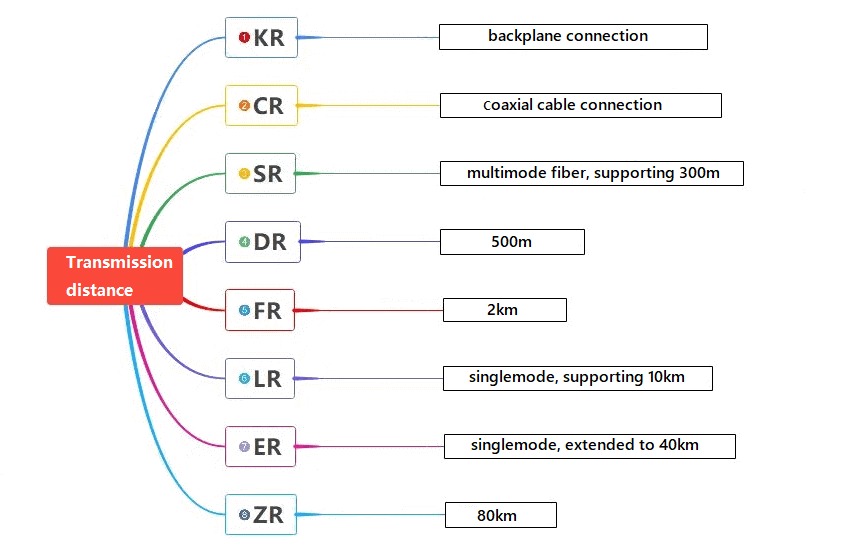

Transmission distance

Do not make the optical module work at the maximum distance for a long time.

How to choose optical module?

How to choose optical module?

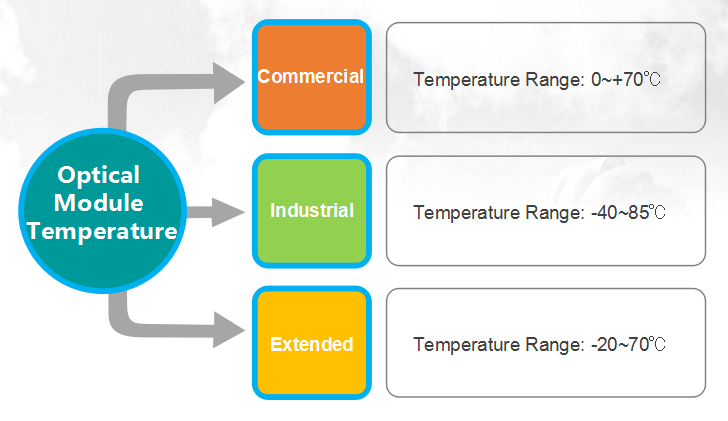

Operating temperature

How to choose optical module?

How to choose optical module?

Equipment brand

Before choosing an optical module, we need to know the brand of the switch. It must be ensured that the optical module has been written with the compatible code of the corresponding brand, and tested on the switch of the corresponding brand to avoid abnormalities in the later work.

A good optical module must pass a number of parameter tests before leaving the factory to ensure the quality of the optical module. It mainly includes eye diagram test, receiving sensitivity, aging test, compatibility test, optical port test and appearance test, etc.

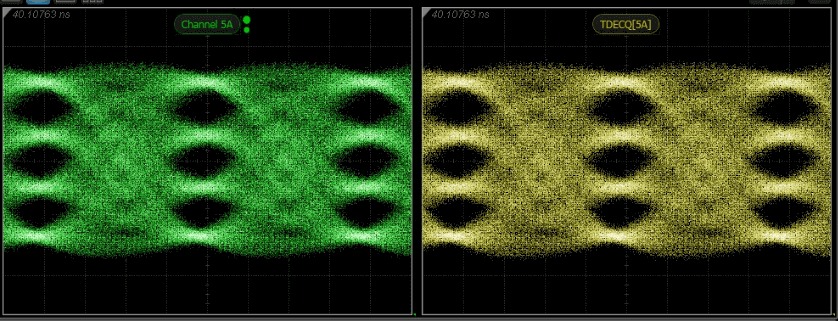

Eye Diagram Detection

The eye diagram is an important stage to ensure that the optical module gets the best signal. It is a series of digital signals accumulated on an oscilloscope and displayed as a graph. It is vividly called an eye diagram because of its shape like an open eye. The quality of the digital signal of the optical module can be seen from the eye diagram test results.

How to choose optical module?

How to choose optical module?

The size of the "eye" of the eye diagram reflects the strength of the intersymbol interference.

The larger the "eye", the more correct the eye diagram and the less crosstalk between codes.

Receiver sensitivity

Receiving sensitivity is one of the key parameters to measure the performance of the receiving end of the optical module. The better the receiving sensitivity, the smaller the minimum received optical power.

aging detection

Aging test is a practical and effective method to predict the lifetime of optical modules and devices. The application environment of the optical module is different, and its working temperature is also different. Before leaving the factory, the optical module must be tested in a high and low temperature aging room to verify whether the performance index of the optical module can still meet the standard in extreme environments.

compatibility test

Compatibility testing is mainly for compatibility testing of compatible modules. Insert the optical module into the switch of the corresponding brand for testing. If the communication is normal, the optical module has passed the test. If communication fails, the optical module is not compatible with it.

Optical port detection

The optical port test is to amplify the optical port before the optical module leaves the factory. In optical communication systems, fiber contamination can cause losses and reflections, leading to high error rates and degraded network performance. Check whether the optical port of the optical module is dirty or scratched.

Visual inspection

Visual inspection involves checking the quality control of optical modules before shipment. Inspect each transceiver's housing for scratches, dirt, color, and smoothness, as well as gold fingers for scratches and tags. Usually, optical modules with poor quality will also have defects in appearance, while high-quality optical modules have a good appearance.