Six Advantages of Single Pair Ethernet Technology

Six Advantages of Single Pair Ethernet Technology

As Single Pair Ethernet (SPE) gains traction in industrial automation, it is important to understand the potential benefits this technology can bring to applications that need to transmit data over long distances but do not have extensive speed or bandwidth requirements. Now is the time to highlight the specific cost, installation, and performance advantages of replacing four-wire lines with two-wire lines so that SPE can be confidently used in practice.

What is Single Pair Ethernet?

Simply put, single-pair Ethernet is a cable configuration that uses a pair of wires (or conductors) to transmit data at speeds of up to 10 Mbps (and possibly up to 1 Gb/s in the future). Designed for industrial users, this single-pair cabling can support up to 52W of DC power, covering a range of power and data-requiring devices at distances up to 1000 meters.

Single-pair Ethernet also provides reliable power (as opposed to wireless) to sensors that are fixed at a physical location and may not have their own power supply.

Single-pair Ethernet is also called "twisted pair" in the standard. The term refers to the fact that a pair consists of a balanced pair of conductors, each carrying a different signal. The most common configuration is to twist two wires together.

Single-pair Ethernet is designed to meet the specific needs of industrial manufacturing users who are OT professionals concerned with connecting low-speed devices such as sensors, actuators and relays, as well as access control and lighting applications.

For their use cases, OT professionals want a simpler, low-cost and space-saving alternative to the ultra-fast 4-pair cabling structure that has become the dominant networking technology in office, telecom and data centers. A single wire is not reliable for technical reasons, so a pair of wires is the simplest and most compact configuration.

OT professionals also need capabilities that complement their specific use cases, where data is often transmitted over long distances to sensors, actuators and other types of connected devices commonly found on the factory floor.

They also require cabling that can be easily retrofitted within existing facilities. From a space perspective, Single-Pair Ethernet can easily replace existing two-wire systems and is compatible with terminal block-style connections commonly found in industrial applications.

Probably the most important benefit of Single Pair Ethernet is that it is a familiar protocol stack, well known to most of the world. The end-to-end Industrial Ethernet network provided by Single Pair Ethernet eliminates the need for a host of proprietary protocols running on various fieldbuses.

Six advantages of single-pair Ethernet technology:

1. Lower capital expenditure

IE (Industrial Ethernet) and SPE connectors are very similar to today's RJ45 and M8 D-coded connectors. Although three-quarters of the wire is removed in the SPE connector, additional filler material is used to maintain the circular shape of the cable. Cost savings between IE and SPE connectors range from 13% to 44%, depending on the type of cable used. Additional savings can be achieved when purchasing greater quantities of connectors.

However, in terms of CAPEX, the most significant savings come from the new network topologies made possible by single-pair Ethernet. For example, eliminating gateways and relying on a single communication network can save over $10,000 per gateway. SPE makes it more economical to integrate sensors and actuators into network infrastructure.

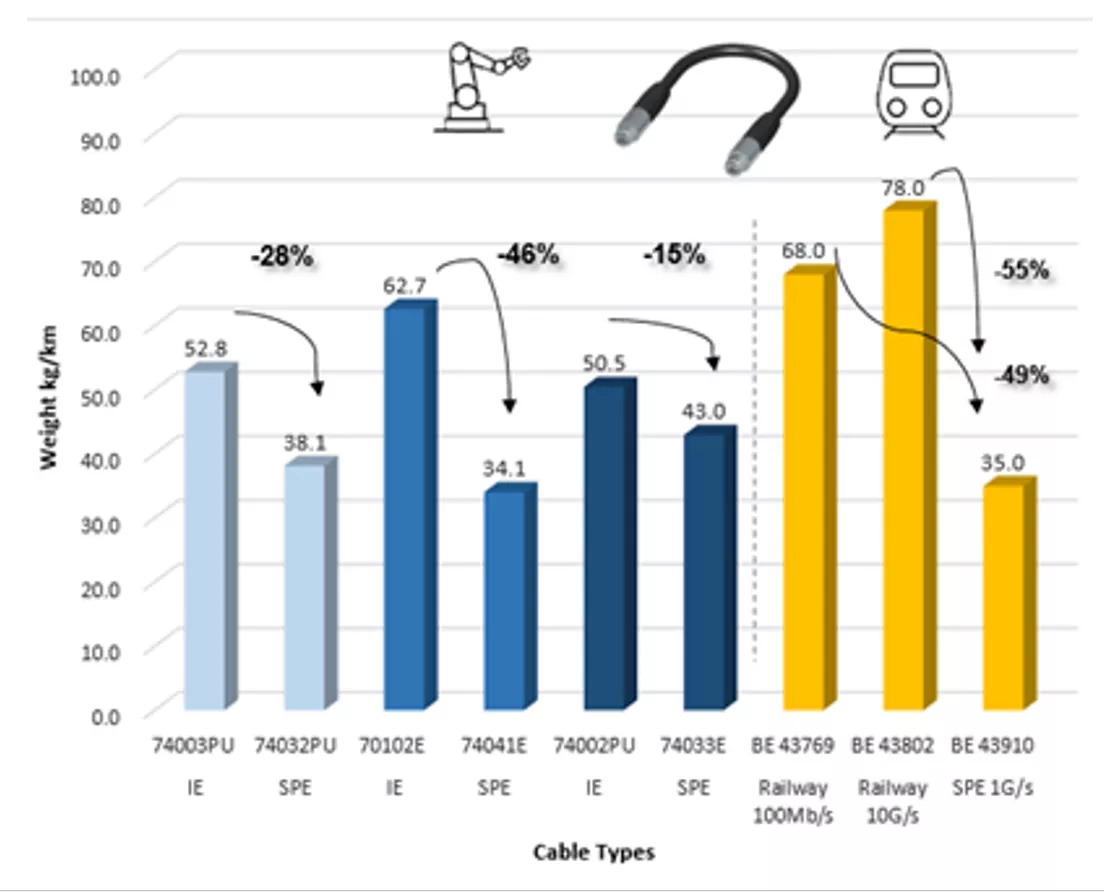

2. Reduced weight and small footprint

Single-pair Ethernet technology allows the use of more compact and lighter cables, with a 50% reduction in weight and 50% reduction in footprint compared to traditional fieldbus cables. This saves valuable space inside the robot as well as on interior walls and floors.

Take electric vehicle production as an example to illustrate these savings. Design engineers are looking for ways to reduce the weight of the chassis to offset the weight of the powertrain, such as batteries and electric motors. For example, some designers have explored ways to remove shielding material from automotive interior wiring harnesses to save weight. SPE offers a potential solution for weight reduction of electric vehicles.

Single-pair Ethernet also plays a vital role in the retrofit of electric vehicles. It is recommended that the vehicle be returned to the factory every 10 years for necessary electronic refurbishment. The structure of the chassis will not change, so the thickness of the interior walls will remain the same. SPE cables can reduce the amount of space required for installation. This weight advantage is in addition to port density (two SPE ports = 1 RJ45 port), which supports more devices in older vehicles.

3. Quick installation and easy maintenance

SPE allows for easy integration of field devices, sensors and actuators into existing Ethernet environments without the need for additional gateways and interfaces, enabling faster and easier installation. This reduces material and labor costs on the new factory floor.

4. Simplify the network

Single Pair Ethernet (SPE) can bring automation systems and traditional industrial networks into a single Ethernet network technology, simultaneously carrying power and data for equipment. Because they are based on the Ethernet protocol, SPE devices generally outperform fieldbus devices.

Migrating sensors and controls to Ethernet using SPE simplifies cabling and management, and potentially eliminates dedicated network equipment, bringing IP communications to the lowest levels of automation.

With SPE, troubleshooting and troubleshooting become much more standardized and accessible than the combination of fieldbus protocols and special decoders and terminations that even the most brilliant skilled technicians need to solve performance problems.

5. Support IT/OT convergence and Sensor to Cloud

The industrial environment of the future will require flexible and adaptable connectivity to meet increasing demands.

SPE is one of the technologies that will contribute to IIoT, Industry 4.0, IT/OT convergence, and seamless data transfer from field-level sensors to the cloud. Together, these innovations create a smart manufacturing environment powered by Single Pair Ethernet.

6. Environmental friendly

Finally, SPE requires fewer natural resources, such as plastic and metal, to build Ethernet-based infrastructure and connectivity assets, helping businesses reduce their carbon footprint and meet ESG goals.

As Industry 4.0 progresses and the number of sensors and actuators connected to the factory backbone continues to grow, single-pair Ethernet will be an easy solution to accelerate industrial automation.