Development of multi-core optical fiber connector technology

Development of multi-core optical fiber connector technology

Ryo Nagase, a professor at Chiba Institute of Technology in Japan, started with an informative introduction, focusing on the research on advancing multi-core fiber optic connector technology.

Japan has been leading the development of optical communication technology since the field of optical communication first appeared. The VAD method, invented in the 1970s, greatly improved performance and reduced fiber manufacturing costs. The technology is still widely used around the world as a mainstream fiber optic manufacturing technique.

Physical contact (PC) technology, invented in the 1980s, also made a major contribution to enabling higher performance optical connectors at lower cost, and it is still used in most types of optical connectors.

These two basic technologies for building optical networks have been recognized as mainstream technologies for more than 25 years since they were introduced into the market, and both have been certified as IEEE milestones.

In Japan, the national optical fiber cable backbone network was completed in 1985, and the world's first commercial fiber-to-the-home (FTTH) service was launched in 2001. There will be 36 million FTTH subscribers in Japan in 2021. The worldwide demand for communication traffic continues to grow, and optical communication systems have undergone tremendous improvements. In 20 years, the signal capacity transmitted through a single optical fiber has increased by about 10,000 times.

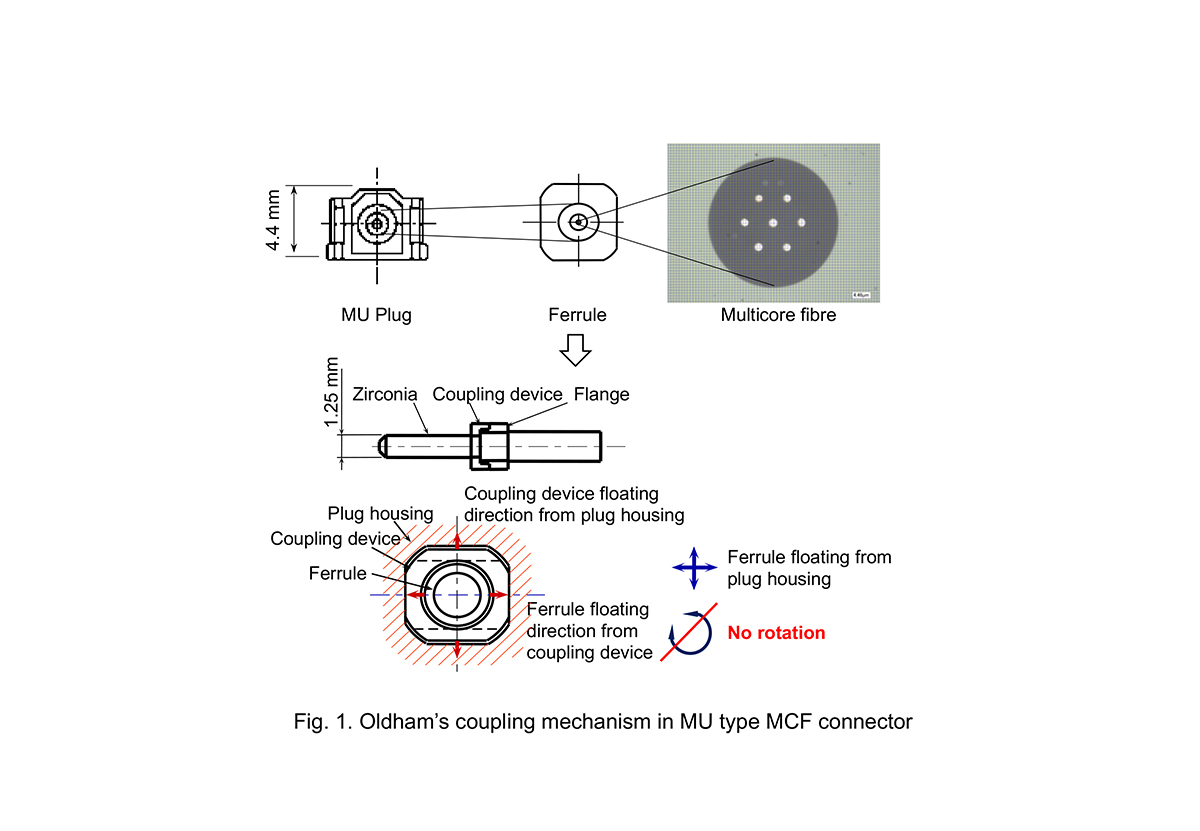

Figure 1: Euclidean coupling mechanism in MU-type MCF connector

On the other hand, single-mode fiber (SMF), currently used as the most broadband medium, has a theoretical limit of 100 Tb/s per fiber, and there are fears of a capacity shortage within a few years if traffic demands continue to increase.

In this context, Japan established the "Extremely Advanced Optical Transmission Technology Technical Committee (EXAT)" in 2008, aiming to further expand optical fiber transmission capabilities. The first such committee in the world, it clarified the concept of Space Division Multiplexing (SDM) technology. One such technique is the use of multicore fibers (MCF). Establishing an optical network with MCF requires new methods, such as MCF manufacturing technology, MCF connection technology (fusion splicing and connectors), MCF and SMF interconnection technology, and MCF optical amplification technology.

This article introduces the MCF optical connector technology first developed by Japan.

Optical connector technology is based

on SMF, and optical signals propagate in an area of about 10 meters, so in order to connect optical fibers, positioning must be performed with high precision better than about 1 meter On the other hand,

in optical connectors, external forces may pass through optical cables effect. In particular, in an optical communication network, optical connectors are mounted on terminal boards at a high density, and line switching work is performed every day in a telephone exchange, so cables of active lines are often touched during work. Even when force is applied to the cable, the connection performance must remain stable.

The optical connector housing is also elastically deformed by a physical contact technique that presses the ferrules together to maintain a stable connection. This deformation can reach tens of meters, making it difficult to guarantee the above-mentioned positioning accuracy required by SMF. To avoid this problem, a floating mechanism is used in which the fiber is fixed in a ferrule and deformation of the housing does not affect the positioning of the fiber.

As mentioned above, the physical contact technology and floating mechanism developed in Japan became the basis of the subsequent optical connector technology, and these technologies are used in the SC type and LC type optical connectors currently in mainstream use.

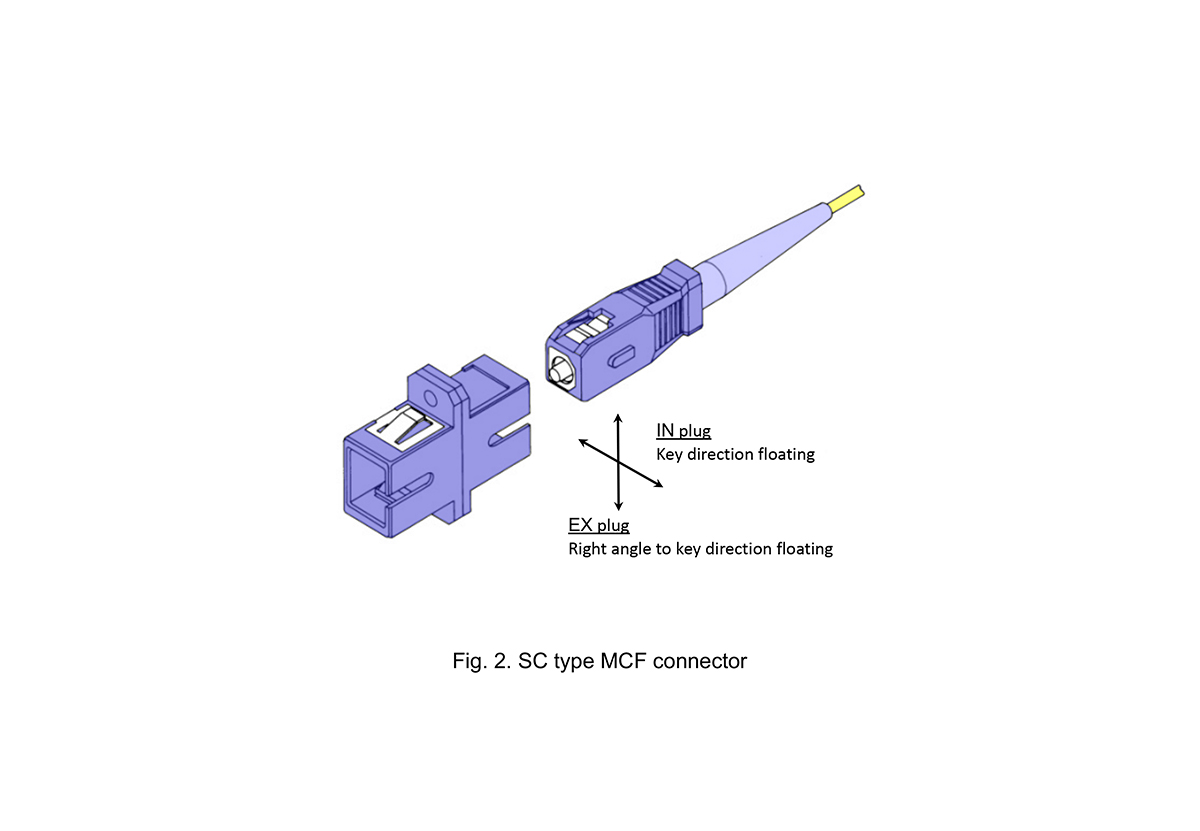

Figure 2: SC type MCF connector

MCF's Optical Connector Technology

In order to connect MCF, it is necessary not only to use a floating mechanism, but also to precisely adjust the rotation angle around the fiber axis. The Oldham coupling is a mechanism that satisfies these conflicting conditions and it has long been used in the field of mechanical engineering. The function of this coupling is to accurately transmit the rotation angle even if there is shaft misalignment, but on the contrary, since shaft misalignment can occur without rotation, it is possible to satisfy the necessary conditions for MCF connectors.

The first practical optical connector for MCF was the MU-type MCF connector developed in Japan in 2012 (Figure 1). By applying Oldham's coupling mechanism, positioning accuracy is maintained, including the angle of rotation. It has the characteristic that the connection loss does not fluctuate even if a tensile load is applied to the cable. In 2019, an SC-type MCF connector was developed that realizes the same principle (2) with a simplified structure (Fig. 2). Practical application of optical connectors to optical communication networks using MCF is in progress.

Conclusion

In the field of optical communications, Japan has made significant contributions to the development of new technologies since the field began. The capacity limitation of current optical communication networks built using SMF has become apparent, so we are conducting research and development to overcome this obstacle.

In Japan, we have developed the basic technology of optical fiber connectors currently used, and are developing new optical fiber connectors for MCF, which are essential for building optical fiber networks using MCF.

References

1. R. Nagase, K. Sakaime, K. Watanabe, and T. Saito, "MU-Type Multi-Core Optical Connectors", in Proc. IWCS2012, 17-2 (November 2012).

2. K. Imaizumi and R. Nagase, "SC-type multi-core fiber optic connector with simplified structure", in Proc. IWCS 2019, 8-1 (2019).