A photoelectric hybrid cable solves the problem of intelligent manufacturing network layout

A photoelectric hybrid cable solves the problem of intelligent manufacturing network layout

Manufacturing has always been the lifeblood of the country's economy. Since the reform and opening up, more than 40 years of development precipitation has transformed China into a manufacturing country, but at present, China's manufacturing industry is still at the middle and low end of the international division of labor, large but not strong problems are prominent, it is imperative to improve quality and efficiency, and the transformation and upgrading are heavy and long.

The clouds in the sky are like white clothes, and Schu is like a dog.

Under the guidance of the "14th Five-Year Plan" intelligent manufacturing development plan, more and more manufacturing enterprises are undergoing digital and intelligent transformation. In the process, manufacturing companies' requirements for network infrastructure are also increasing.

At a time when emerging technologies and advanced manufacturing are accelerating their convergence, how to build a solid and powerful network infrastructure to ensure the stable operation of enterprise networks, the efficient flow of data, and the continuous development of services? This is a topic that every manufacturing company must face on the road to transformation.

The Dilemma of Laying the Net: From "Manufacturing" to "Intelligent Manufacturing"

In September, Wang Jianwei, deputy director of the Information Technology Development Department of the Ministry of Industry and Information Technology, introduced at a press conference that as of the second quarter of this year, the proportion of China's manufacturing enterprises achieving intelligent production was 6.6%. It can be seen that to move towards intelligent manufacturing, there are still obstacles and long ways for most enterprises. At present, the network problems faced by manufacturing enterprises are mainly concentrated in three aspects:

One. The number of information points and data acquisition terminals has grown massively, and the basic network structure is complex. With the in-depth application of 5G technology and the gradual development of "Industry 4.0", "black light factories" that have realized the automation and intelligence of the whole process have gradually emerged. The introduction of massive intelligent terminals has led to the complexity of network structure.

Two. The demand for rapid service provisioning and standardized management has increased. Since the outbreak of the epidemic, the concept of flexible production has gradually taken root in the hearts of the people. Intelligent manufacturing with flexible production characteristics allows enterprises to rebuild a personalized production line in a short period of time and promote rapid product update and iteration. How to support this need for rapid iteration is a real test for enterprise networks.

Three. Information security under the normalization of mobile office. Data leakage incidents occur from time to time in office scenarios in manufacturing enterprises, such as untrusted applications used for office, non-compliant access by all parties, and phishing software by employees by mistake. How to ensure information security from the network level is still worth pondering.

The manufacturing industry should move towards intelligent manufacturing, whether it is in network performance, transmission distance, deployment, operation and maintenance, cost and other levels have higher requirements.

When the information points of the production workshop continue to increase; When the camera resolution is upgraded from 1080P to 4K and 8K; Under the trend of mobile office, the number of terminals connected to the intranet is increasing. These bandwidth-eating changes pose challenges to traditional Ethernet networks with copper as the main medium. The upgrade of transmission media has naturally become the consensus in the industry.

The way to break the game: the meaning of a photoelectric hybrid cable condensation

In recent years, the concept of "optical input and copper retreat" has been extended from home broadband to enterprise-level campus networks, and "all-optical networks" that meet the characteristics of high bandwidth, low latency, and high speed have been recognized and accepted by more and more enterprises. It is undeniable that compared to copper cable, fiber has almost no bandwidth bottleneck and can smoothly evolve to hundreds of gigabytes; The wiring can be up to 100 kilometers long, covering every corner of the park, while the transmission distance of copper cables is limited to 100 meters. However, for manufacturing parks, fiber optics cannot completely replace copper.

光纤固然可以解决性能和传输距离的问题,但是以玻璃纤维为原材料的光纤是绝缘体,无法直接取代铜缆的PoE供电方式。视频监控、无线AP、接入交换机等大量设备只能本地取电,对于部署拉线、点位扩展、弱电间设备管理、用电安全来说难度增大。

现在的制造业需要的是一张既能发挥光纤的强大性能,又要保证供电覆盖、点位扩展和运维体验的基础网络,以适应不同场景下的用网需求。

面对这一新需求,ICT基础设施及解决方案提供商锐捷网络提供了一种新解法——光电混合缆。所谓光电混合缆,就是将光纤和铜导线集成在一根线缆中,数据通过光纤可以完成高速率、远距离的传输,供电通过铜缆可以完成长距离供电,避免本地取电。这样一来,就达成了取两家之长,实现一线两用的目的。

使用铜缆PoE供电仍旧走不出100m的衰减困境,而锐捷采用的光电混合缆则能支持PoF(Power over the Fiber)供电,2.5mm²规格的线缆可以支持最远2.5km的供电,配合上光纤远超铜缆的网络传输距离,可以说是信息点位“指哪打哪”。

根据制造企业内部生产、办公和办公场景,锐捷网络针对性地推出了光电一体化创新产品——框式时光主机RG-S7808C-V2、盒式时光主机RG-S5750-DP系列。时光主机系列支持对多种型号的远端模块的供电/光纤传输一体化,业务场景覆盖全面;可以实现长距离集中供电、断电不断网;集中部署减少弱电间和网线数量,有效解决弱点间多管控难等问题。

据介绍,光电一体化系列交换机的多形态设计针对的智能制造中的不同应用场景。

- 框式时光主机RG-S7808C-V2面向的是中型制造企业生产车间的核心,覆盖1万到2万平米

- 24口盒式时光主机面向的是大型制造业园区的汇聚,保障三层的网络架构可以承载更多设备

- 48口的盒式支持48口对外供电,单口支持30W供电功率,主要定位在办公场景

此外,为了配合企业园区极简以太全光网络解决方案V2.2,锐捷也推出了光电一体化极简光入室交换机RG-IF2920系列和RG-PF2920系列等,匹配不同企业场景下的网络部署需求。

归根结底,新产品功能的研发制造和多样的规格设计,都基于锐捷精益求精的实践精神,每次迭代升级都源于用户的实际需求,这一点贯穿在极简光历代方案和产品的设计中。

研发之旅:极简以太全光网从1.0到2.2

2021年3月,面向不断升温的全光网络市场需求,锐捷网络对外发布了极简以太全光网络1.0。这套精心打造、筹备良久的解决方案为企业网络升级提供了新的路径。此后,锐捷网络又在此基础上进行了全新升级,而针对制造行业,锐捷推出了适配性的光电一体化解决方案——企业园区极简以太全光网络解决方案V2.2(以下简称“极简光2.2”)。

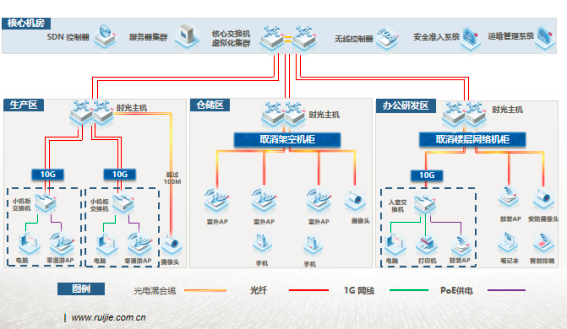

企业园区极简以太全光网络解决方案V2.2——全景图

相较于1.0版本,新一代的极简光2.2有哪些硬核升级?在版本迭代时其核心研发需求是否有所变化?研发团队基于哪些痛点对相关产品进行了针对性设计?锐捷网络交换路由产品事业部产品总监高振向记者介绍了背后的故事。

高振提到,和上一代解决方案相比,极简光2.2主要在两大层面进行了重点革新。

其一,在产品的软、硬件设计上,更符合制造行业细分场景需求。在硬件上,提高实用性和性价比,除了推出新产品外,还改善了原有的产品系列更适配光电一体化的需求。同时,在软件上,更加注重运维管理的精细化和智能化。光电一体化不仅仅是物理上的一体化,在设备、线缆运维层面也实现了一体化。延续了1.0的“零配置上线”“零配置替换”“环路自愈”“光链路检测”等智能运维的同时,极简光2.2增加了“光电一体运维”、“哑终端智能识别”等功能,尽可能减少在运维管理层面的压力。

其二,在网络架构上,锐捷认为园区网络未来会走向“LAN-WAN融合”。“由于园区路由交换方案种类很多,方案与方案之间其实是彼此隔离的,如果要同时采用多个方案,对用户来说,容易形成‘方案烟囱’,导致各个子方案之间彼此隔离。未来我们希望自己更多的是提供端到端的解决方案。”而且在移动办公、万物互联,以及IPv6的发展的驱动下,LAN与WAN的边界正在变得模糊。实现LAN/WAN统一纳管,从而降低管理成本、提升整体网络效率等,是未来园区网络的发展和厂商的研究方向。

尽管新一代解决方案里有不少创新性设计,但高振强调,总体来说,核心研发需求是一以贯之的,那就是——始终以客户为中心,为其实现降本增效。“帮助客户筛选出网络建设中没必要花钱的点并进行精简,比如布线施工,这些环节花费再多对于网络质量的提升并没有任何实质好处。反之,如果在带宽的升级、时延的降低等方面多做投入,那效果必然立竿见影。”

扎根行业场景:我们的技术梦想终将伸手可及

“扎根行业,深入场景”一直是锐捷网络进行研发与创新时坚持的理念。极简光2.X方案在制造业的应用落地对此做了恰如其分的诠释。

生产场景中,传统方案往往因为信息点的变动面临施工难、周期长的挑战,加上重点区域车间大机柜需要独立部署UPS电源,成本高昂。而采用极简光2.X方案,时光主机通过光电混合缆统一为各种类型设备供电,降低UPS部署成本;光纤到接入交换机,未来调整布线、拆线成本再降低;管控上各类终端连通状态实现可视化管理。

在仓储场景中,由于仓储环境所限,传统方案中仓储交换机通常部署在高空桥架,高空维护难,而且布线大于100M,需要额外部署PoE交换机,整体成本高且线路利用率低。而采用极简光2.X方案,时光主机统一管理,无高空作业;AP虚拟化,同频零漫游AGV/PDA不掉线;全光仓储部署,节约仓储PoE交换机至少60%。

在办公场景中,楼层信息点数量众多,传统布线不灵活,弱电间众多,管理成本高。加上业务互访频繁,无线用户难管控,安全策略变更频繁。而采用极简光2.X方案,光纤入室,显著减少布线和楼层弱电间;全光接入,业务扩展无需重新布线;交换机、弱电箱一体设计,易安装;SDN控制器自动适配,身份,网络安全策略,无需人工干预。